Technical Services

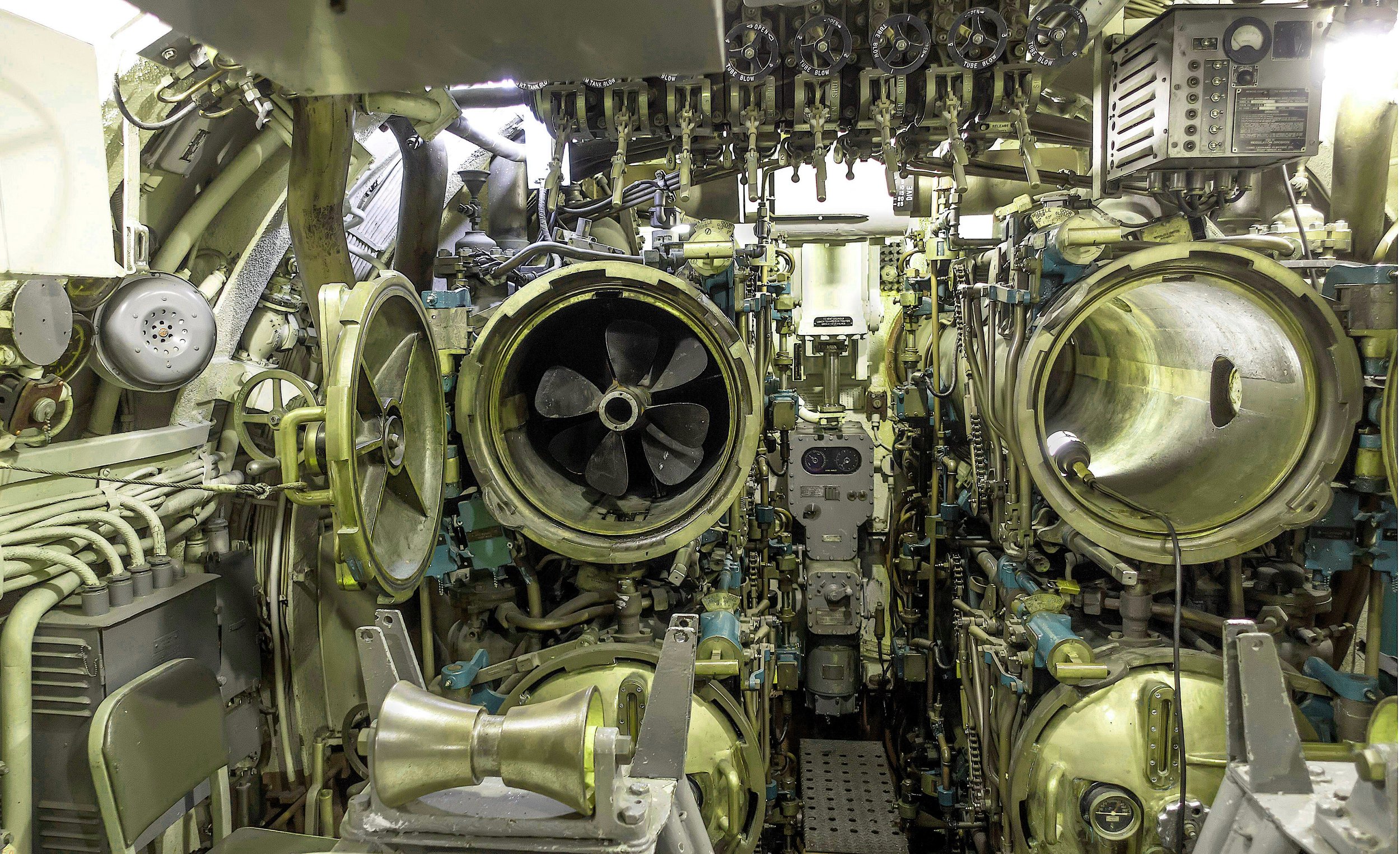

If you want to start manufacturing LEVEL I Nuclear Submarine Components for the US Navy, that means adhering to the most rigorous quality system on the planet.

Fortunately for you, we’ve already done the hard part–and now we’re sharing our secrets for the success of the mission.

You’re not in this alone.

It’s imperative to global security and stability that the United States ramp up the production of Navy Nuclear submarines as quickly as possible.

Cogitic has the technical expertise from over a decade of manufacturing critical components like main shaft seals to support America’s partners in this endeavor.

Having successfully completed hundreds of engineering-driven projects in the Navy Nuclear field, our technical services will be invaluable to any manufacturer looking to take on this demanding work.

Expert Engineering Support

Our in-house engineering team can support you with everything from new product design, optimizing designs for manufacturing, submitting technical justification of waiver requests and other highly complex engineering functions.

• Standard clause and flow down tools

• Pre-audit and QMS audit support

• Material traceability systems

• Workforce training systems

• Marking and identification procedures

• Weld procedures

• NDT procedures

• Design and system development

• Simulation and test plan development

• Technical documentation development

• Contract review procedures

• Submittal management

• Project management tools

• Purchasing system procedures

Manufacturing Process Mastery

By heavily investing in our people, systems, and procedures over the last decade, we’ve been able to condense extremely complicated machining, welding, and testing requirements into something we can train your team to execute efficiently. Specializing in the machining of HRSA (heat resistant super alloys) and assembly of critical systems, our manufacturing procedures have been designed and calibrated to perfection.

Capabilities include:

5-axis mill-turn (up to ø60” x 72”)

Heavy turning (ø32” x 200”)

Wire and sinker EDM

Deep hole drilling

Cylindrical, jig and surface grinding

Lapping, honing and automated polishing

Pallet systems allowing for unattended operation

On-machine probing and in-process dimensional validation

Automatic tool setting (on-machine and off-machine via pre-setting)

Complex assembly of small to medium-size systems (mechanical, electrical and opto-mechanical)

Characterization of in-service components and assemblies

Repair, rebuild and validation of assemblies (seal rings, ball valves, strainers, valve components, etc.)

Testing, Inspection, and Quality Systems

Our technical services team can support you with everything from inspection and testing procedures to implementing rigorous quality management systems to submitting technical justification of waiver requests, and other highly complex technical functions.

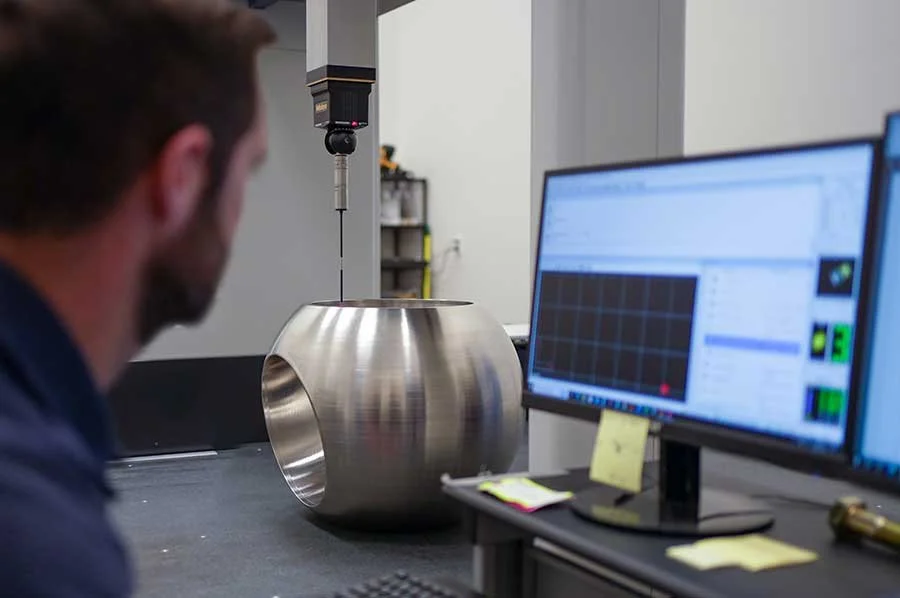

In-House Inspection

Dimensional metrology expertise for all features

Large format CMMs

System 21/22/23 thread gauging

Long Form 3rd party calibration

Material and Product Testing

Positive material identification

Hydrostatic

Flow and acoustic

Gas leakage

Chemical and mechanicals

Thermal shock

Temperature and humidity

Quality Management Systems

EB2678

MIL-I-45208

MIL-STD-45662

ISR-1

STR9000

AS9100

ISO 9001

Get direct access to the technical expertise you need to start manufacturing components and assemblies for the biggest shipbuilders in the world.

As a longtime partner to Northrop Grumman Marine Systems, General Dynamics Electric Boat, Newport News, and other top players, Cogitic’s technical services team will save you thousands of hours of work and worry.